In concrete construction today, the best projects combine environmentally conscious practices with labor-saving techniques. One critical component, concrete reinforcement, is undergoing a revolutionary advancement with the adoption of composite reinforcements to replace steel rebar and mats. Into this evolution steps BASTECH basalt fiber reinforced polymer rebar. BASTECH rebar, made from abundant volcanic rock, addresses both the environmental and labor-saving goals of today’s engineers, architects and specifiers.

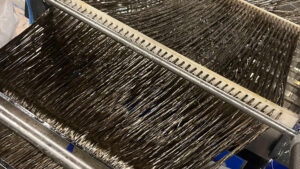

Comprised of basalt fibers consolidated with a polymer coating, BASTECH BFRP has 2.5 times the strength of steel, while weighing just 25% of steel. It will never rust and will never corrode, which means no spalling or concrete degradation. It is non-conductive, so it is transparent to magnetic fields. The light weight makes BASTECH rebar easy to transport and move on the jobsite, saving time, labor and shipping costs. And, most importantly, the production of BASTECH rebar requires 60% less CO2 than conventional steel reinforcement.

There are many situations in which BASTECH rebar provides substantial benefits over steel reinforcement. Here are a few:

Concrete structures susceptible to corrosion. As every engineer and architect knows, concrete cracks. When a crack develops, the steel reinforcement inside is exposed to moisture, which starts a downward cycle of rusting and more extensive cracking that can severely degrade the structure. Just look at some of our failing bridges and roadways today. You’ll likely see rusted concrete jutting out of the cracks. BASTECH reinforcement eliminates that rust-corrosion cycle and is an especially desirable steel substitute in saltwater environments such as coastal regions and roadways where salt is used during winter months.

Concrete structures requiring non-ferrous reinforcement. This would include hospitals, datacenters and other structures where steel reinforcement can interfere with electromagnetic waves. Because BASTECH rebar is non-conductive, it will not interfere with electromagnetic signals that are critical to the operations inside these facilities.

Tunnels and mining industry. The environmental properties of basalt-fiber rebar make BASTECH ideal in the tunneling and mining industries, where machinery will “consume” reinforced concrete members.

Low-demand slab applications and other structures. Residential driveways, pools and wall and pool coping, seawalls, curbs and concrete structures located under water and in marine environments.